From the Ruby kit manual I am reading that you adjust the reversing valve so that when the reversing lever is in the forward position the groove on the valve is just touching the back side of the valve assembly.

Out of the factory, mine does the opposite unless I am mistaken about what is forward/reverse:

To me, this is in reverse

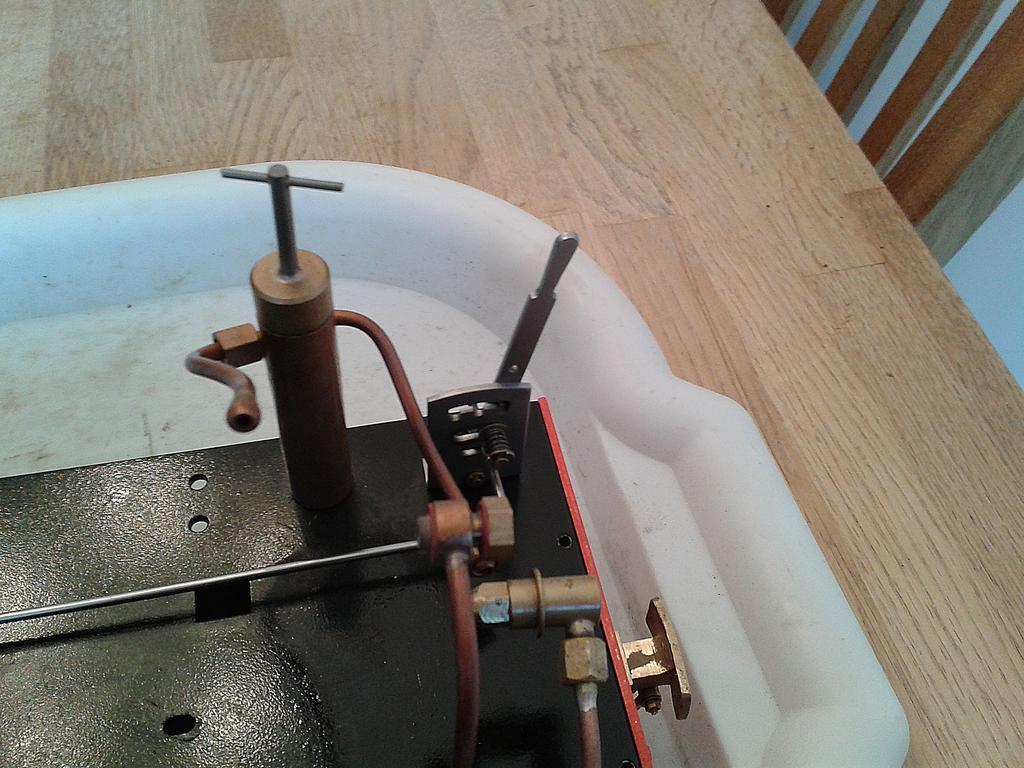

And yet the reversing valve is touching the back side of the valve assembly:

Put the reversing lever in forward and then then valve is no where near the valve assembly:

Could someone have a look at their Edrig, Ragleth, etc please and tell me how it is set up?